Cov tshuab ua kom txias kua nitrogen siv dav hauv kev lag luam semiconductor & chip, suav nrog cov txheej txheem ntawm,

- Cov thev naus laus zis ntawm Molecular Beam Epitaxy (MBE)

- Qhov kev sim ntawm lub chip tom qab pob COB

Cov Khoom Sib Xws

Molecular Beam EPITAXY

Cov thev naus laus zis ntawm Molecular Beam Epitaxy (MBE) tau tsim nyob rau xyoo 1950 los npaj cov ntaub ntawv semiconductor nyias zaj duab xis siv cov thev naus laus zis nqus tsev vacuum. Nrog rau kev txhim kho ntawm cov thev naus laus zis ultra-high vacuum, daim ntawv thov thev naus laus zis tau nthuav dav mus rau thaj chaw ntawm kev tshawb fawb semiconductor.

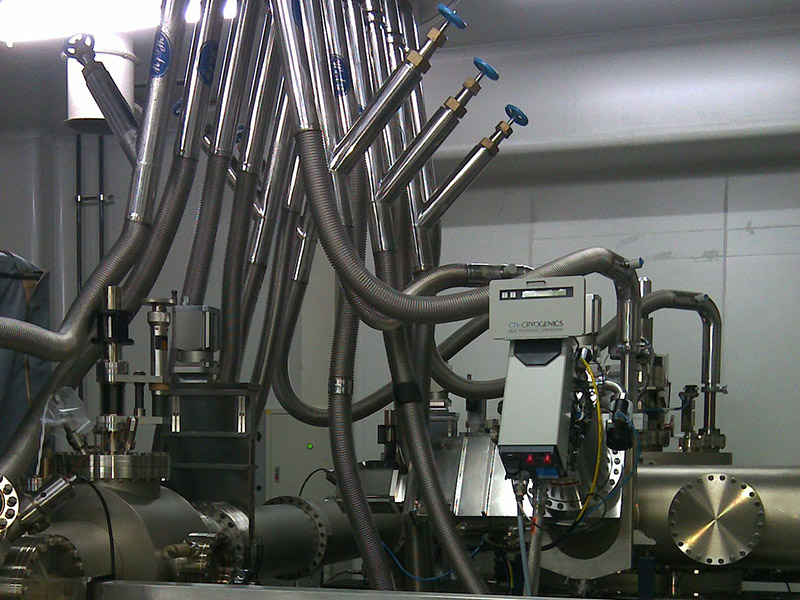

HL tau pom qhov kev thov ntawm MBE kua nitrogen txias system, teeb tsa cov txheej txheem kev siv tshuab los ua kom tiav tsim ib qho tshwj xeeb MBE kua nitrogen cooing system rau MBE technology thiab ib txheej tiav ntawm lub tshuab nqus tsev insulated piping system, uas tau siv hauv ntau lub tuam txhab, tsev kawm qib siab thiab cov koom haum tshawb fawb.

Cov teeb meem feem ntau ntawm kev lag luam semiconductor & chip suav nrog,

- Lub Siab ntawm Cov Kua Nitrogen rau hauv Cov Khoom Siv Terminal (MBE). Tiv thaiv kom tsis txhob muaj kev puas tsuaj rau Cov Khoom Siv Terminal (MBE).

- Ntau yam Cryogenic Kua Inlet thiab Outlet Controls

- Qhov Kub ntawm Cov Kua Nitrogen rau hauv Cov Khoom Siv Kawg

- Cov Pa roj Cryogenic Tsim Nyog

- (Tsis Siv Neeg) Kev Hloov Cov Kab Loj thiab Cov Kab Ceg

- Kev Kho Siab (Txo) thiab Kev Ruaj Ntseg ntawm VIP

- Kev Ntxuav Cov Khoom Tsis Huv thiab Cov Dej Khov ntawm Lub Tank

- Lub Sijhawm Sau ntawm Cov Khoom Siv Kua Terminal

- Kev Ua Ntej Txias Rau Cov Kav Dej

- Kev Tiv Thaiv Kua Hauv VIP System

- Tswj Kev Poob ntawm Cov Kua Nitrogen Thaum Lub Sijhawm Tsis Txuas Ntxiv ntawm Lub Tshuab

HL lub Vacuum Insulated Pipe (VIP) yog ua raws li ASME B31.3 Pressure Piping code ua tus qauv. Kev paub txog engineering thiab kev tswj xyuas zoo kom ntseeg tau tias cov neeg siv khoom lub Hoobkas ua haujlwm tau zoo thiab tsim nyog tus nqi.

KEV DAWS TEJ YAM

HL Cryogenic Equipment muab cov neeg siv khoom nrog Lub Tshuab Nqus Tsev Insulated Piping System kom ua tau raws li cov kev cai thiab cov xwm txheej ntawm kev lag luam semiconductor & chip:

1. Kev Tswj Xyuas Zoo: ASME B31.3 Cov Cai Kav Dej Siab.

2. Ib qho Chaw Sib Cais Tshwj Xeeb nrog Ntau Qhov Cryogenic Kua Nkag thiab Qhov Tawm nrog kev tswj hwm tsis siv neeg ua tau raws li qhov yuav tsum tau ua ntawm cov pa roj, cov kua nitrogen rov ua dua tshiab thiab qhov kub ntawm cov kua nitrogen.

3. Tsim kom muaj pa tawm zoo thiab raws sijhawm kom ntseeg tau tias cov khoom siv davhlau ya nyob twg yeej ib txwm ua haujlwm hauv tus nqi siab tsim.

4. Lub Rooj Tswj Xyuas Roj-kua tau muab tso rau hauv lub yeeb nkab VI ntsug ntawm qhov kawg ntawm lub yeeb nkab VI. Lub Rooj Tswj Xyuas Roj-kua siv lub hauv paus ntsiab lus ntawm lub foob roj los thaiv cov cua sov ntawm qhov kawg ntawm lub yeeb nkab VI mus rau hauv lub yeeb nkab VI, thiab txo qhov poob ntawm cov kua nitrogen thaum lub sijhawm ua haujlwm tsis tu ncua thiab tsis tu ncua ntawm lub kaw lus.

5.VI Cov Kav Dej Tswj Los Ntawm Lub Tshuab Nqus Tsev Insulated Valve (VIV) Series: Xws li Lub Tshuab Nqus Tsev Insulated (Pneumatic) Shut-off Valve, Lub Tshuab Nqus Tsev Insulated Check Valve, Lub Tshuab Nqus Tsev Insulated Regulating Valve thiab lwm yam. Ntau hom VIV tuaj yeem ua ke ua ke los tswj VIP raws li qhov xav tau. VIV tau koom ua ke nrog VIP prefabrication hauv chaw tsim khoom, tsis muaj kev kho mob Insulated hauv qhov chaw. Lub tshuab foob ntawm VIV tuaj yeem hloov tau yooj yim. (HL lees txais lub npe cryogenic valve uas cov neeg siv khoom xaiv, thiab tom qab ntawd ua lub tshuab nqus tsev insulated valves los ntawm HL. Qee lub npe thiab cov qauv ntawm cov li qub yuav tsis tuaj yeem ua rau lub tshuab nqus tsev insulated li qub.)

6. Kev huv, yog tias muaj cov kev cai ntxiv rau kev ntxuav qhov chaw ntawm lub raj sab hauv. Nws raug pom zoo kom cov neeg siv khoom xaiv cov kav hlau tsis xeb BA lossis EP ua cov kav hlau sab hauv VIP kom txo qis cov hlau tsis xeb nchuav ntxiv.

7. Lub Tshuab Nqus Tsev Insulated: Ntxuav cov khoom tsis huv thiab cov dej khov ntawm lub tank.

8. Tom qab kaw lossis kho ob peb hnub lossis ntev dua, nws yog qhov tsim nyog heev uas yuav tsum tau ua ntej txias cov kav dej VI thiab cov khoom siv kawg ua ntej nkag mus rau hauv cov kua cryogenic, kom tsis txhob muaj dej khov tom qab cov kua cryogenic nkag mus rau hauv cov kav dej VI thiab cov khoom siv kawg. Kev ua haujlwm ua ntej txias yuav tsum tau xav txog hauv kev tsim qauv. Nws muab kev tiv thaiv zoo dua rau cov khoom siv kawg thiab cov khoom siv txhawb nqa VI Piping xws li cov li qub.

9. Haum rau ob qho tib si Dynamic thiab Static Vacuum Insulated (Flexible) Piping System.

10. Lub Tshuab Nqus Tsev Uas Muaj Cov Yeeb Nkab ...

11. Ntau Hom Kev Txuas: Hom Kev Txuas Nqus Tsev Bayonet (VBC) thiab Hom Kev Txuas Welded tuaj yeem xaiv tau. Hom VBC tsis xav tau kev kho mob rwb thaiv tsev hauv tsev.