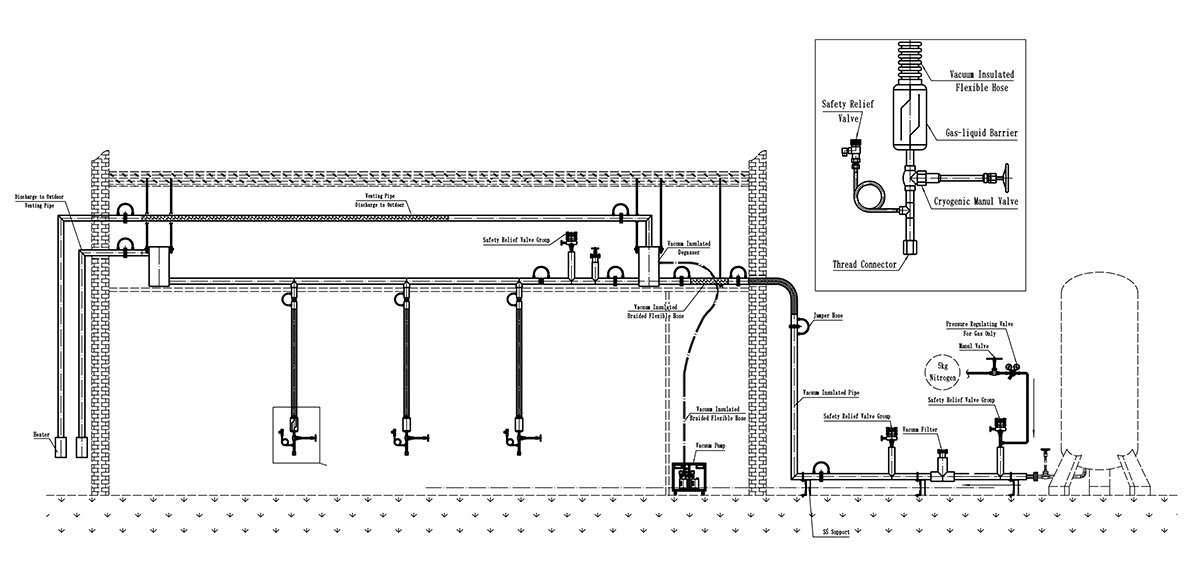

Kev tsim khoom thiab tsim qauv ntawm Lub Tshuab Nqus Tsev Insulated Piping System rau kev xa cov kua nitrogen yog lub luag haujlwm ntawm tus neeg muag khoom. Rau qhov project no, yog tias tus neeg muag khoom tsis muaj cov xwm txheej rau kev ntsuas ntawm qhov chaw, cov duab kos ntawm cov kav dej yuav tsum tau muab los ntawm lub tsev. Tom qab ntawd tus neeg muag khoom yuav tsim VI Piping System rau cov xwm txheej kua nitrogen.

Tus neeg muag khoom yuav tsum ua kom tiav qhov kev tsim qauv ntawm lub raj xa dej los ntawm cov neeg tsim qauv paub dhau los raws li cov duab kos, cov khoom siv, cov xwm txheej ntawm qhov chaw, cov yam ntxwv ntawm cov kua nitrogen thiab lwm yam uas tus neeg thov tau muab.

Cov ntsiab lus ntawm tus qauv tsim muaj xws li hom khoom siv ntawm lub kaw lus, kev txiav txim siab ntawm cov khoom siv thiab cov lus qhia ntawm cov kav dej sab hauv thiab sab nraud, kev tsim cov txheej txheem rwb thaiv tsev, cov txheej txheem seem ua ntej, daim ntawv sib txuas ntawm cov ntu yeeb nkab, lub yeeb nkab sab hauv, tus lej thiab txoj haujlwm ntawm lub qhov nqus tsev, kev tshem tawm cov roj foob, cov kua cryogenic xav tau ntawm cov khoom siv davhlau ya nyob twg, thiab lwm yam. Cov txheej txheem no yuav tsum tau txheeb xyuas los ntawm cov neeg ua haujlwm tshaj lij ntawm tus neeg thov ua ntej tsim khoom.

Cov ntsiab lus ntawm Vacuum Insulated Piping System tsim yog dav, ntawm no rau HASS daim ntawv thov thiab MBE cov khoom siv hauv qee qhov teeb meem tshwm sim, kev sib tham yooj yim.

VI Cov Kav Dej

Lub tank cia kua nitrogen feem ntau ntev ntawm HASS Daim Ntawv Thov lossis MBE cov khoom siv. Thaum lub raj xa dej nqus tsev nkag mus rau hauv tsev sab hauv tsev, nws yuav tsum tau zam kom tsim nyog raws li qhov chaw hauv tsev thiab qhov chaw ntawm cov yeeb nkab teb thiab cov kav dej cua. Yog li ntawd, thauj cov kua nitrogen mus rau cov khoom siv, tsawg kawg yog ntau pua meters ntawm cov yeeb nkab.

Vim tias cov kua nitrogen uas raug nias nws tus kheej muaj cov roj ntau heev, ua ke nrog qhov deb ntawm kev thauj mus los, txawm tias lub raj xa dej adiabatic yuav tsim cov nitrogen ntau heev hauv cov txheej txheem thauj mus los. Yog tias cov nitrogen tsis raug tso tawm lossis cov pa tawm tsawg dhau los ua kom tau raws li qhov yuav tsum tau ua, nws yuav ua rau cov roj tsis kam thiab ua rau cov kua nitrogen ntws tsis zoo, ua rau cov nqi ntws tsawg heev.

Yog tias qhov ntws tsis txaus, qhov kub hauv lub chamber kua nitrogen ntawm cov khoom siv tsis tuaj yeem tswj tau, uas thaum kawg yuav ua rau puas tsuaj rau cov khoom siv lossis cov khoom zoo.

Yog li ntawd, nws yog ib qho tsim nyog los xam qhov ntau ntawm cov kua nitrogen siv los ntawm cov khoom siv kawg (HASS Daim Ntawv Thov lossis MBE khoom siv). Tib lub sijhawm, cov lus qhia ntawm cov kav dej kuj raug txiav txim siab raws li qhov ntev thiab kev coj ntawm cov kav dej.

Pib ntawm lub tank cia kua nitrogen, yog tias lub raj xa dej tseem ceeb ntawm cov yeeb nkab / hose rwb thaiv tsev yog DN50 (lub cheeb sab hauv φ50 mm), nws ceg VI yeeb nkab / hose yog DN25 (lub cheeb sab hauv φ25 mm), thiab cov yeeb nkab ntawm cov yeeb nkab ceg thiab cov khoom siv kawg yog DN15 (lub cheeb sab hauv φ15 mm). Lwm cov khoom siv rau VI piping system, suav nrog Phase Separator, Degasser, Automatic Gas Vent, VI/Cryogenic (Pneumatic) Shut-off Valve, VI Pneumatic Flow Regulating Valve, VI/Cryogenic Check Valve, VI lim, Safety Relief Valve, Purge system, thiab Vacuum Twj Tso Kua Mis thiab lwm yam.

MBE Lub Tshuab Sib Cais Theem Tshwj Xeeb

Txhua lub MBE tshwj xeeb siab ib txwm muaj cov haujlwm hauv qab no:

1. Lub ntsuas ntsuas qib kua thiab lub kaw lus tswj qib kua tsis siv neeg, thiab tso tawm sai sai los ntawm lub thawv tswj hluav taws xob.

2. Kev ua haujlwm txo qhov siab: qhov nkag ntawm cov kua ntawm lub separator muaj lub kaw lus pabcuam separator, uas lav qhov siab ntawm cov kua nitrogen ntawm 3-4 bar hauv cov yeeb nkab tseem ceeb. Thaum nkag mus rau hauv Phase Separator, maj mam txo qhov siab kom ≤ 1Bar.

3. Kev tswj cov kua dej nkag: muaj lub kaw lus tswj kev ntab dej nyob hauv lub Phase Separator. Nws lub luag haujlwm yog kho qhov ntau ntawm cov kua dej thaum cov kua nitrogen noj ntau ntxiv lossis tsawg dua. Qhov no muaj qhov zoo ntawm kev txo qhov kev hloov pauv ntawm lub siab uas tshwm sim los ntawm kev nkag ntawm cov kua nitrogen ntau thaum lub qhov nkag pneumatic valve qhib thiab tiv thaiv kev siab dhau.

4. Kev ua haujlwm tsis zoo, qhov ntim zoo hauv lub separator lav qhov siab tshaj plaws ntawm qhov ntws tam sim ntawd ntawm lub cuab yeej.

5. Lub kaw lus ntxuav: cua thiab dej pa hauv lub separator ua ntej cov kua nitrogen hla, thiab tso tawm cov kua nitrogen hauv lub separator tom qab cov kua nitrogen hla.

6. Kev ua haujlwm tsis siv neeg overpressure: Cov khoom siv, thaum pib dhau los ntawm cov kua nitrogen lossis nyob rau hauv qhov xwm txheej tshwj xeeb, ua rau muaj kev nce ntxiv ntawm cov kua nitrogen gasification, uas ua rau muaj kev ntxhov siab tam sim ntawd ntawm tag nrho lub kaw lus. Peb Lub Separator Theem tau nruab nrog Safety Relief Valve thiab Safety Relief Valve Group, uas tuaj yeem ua kom zoo dua qhov ruaj khov ntawm lub siab hauv lub separator thiab tiv thaiv cov khoom siv MBE kom tsis txhob raug puas tsuaj los ntawm kev ntxhov siab ntau dhau.

7. Lub thawv tswj hluav taws xob, qhov tso saib tiag tiag ntawm cov kua theem thiab tus nqi siab, tuaj yeem teeb tsa cov kua theem hauv lub tshuab cais thiab cov kua nitrogen rau hauv qhov ntau ntawm kev tswj hwm kev sib raug zoo. Tib lub sijhawm. Thaum muaj xwm txheej ceev, tes nres ntawm lub tshuab cais roj kua rau hauv lub qhov tswj kua, rau cov neeg ua haujlwm hauv qhov chaw thiab cov khoom siv kev nyab xeeb los muab kev lees paub.

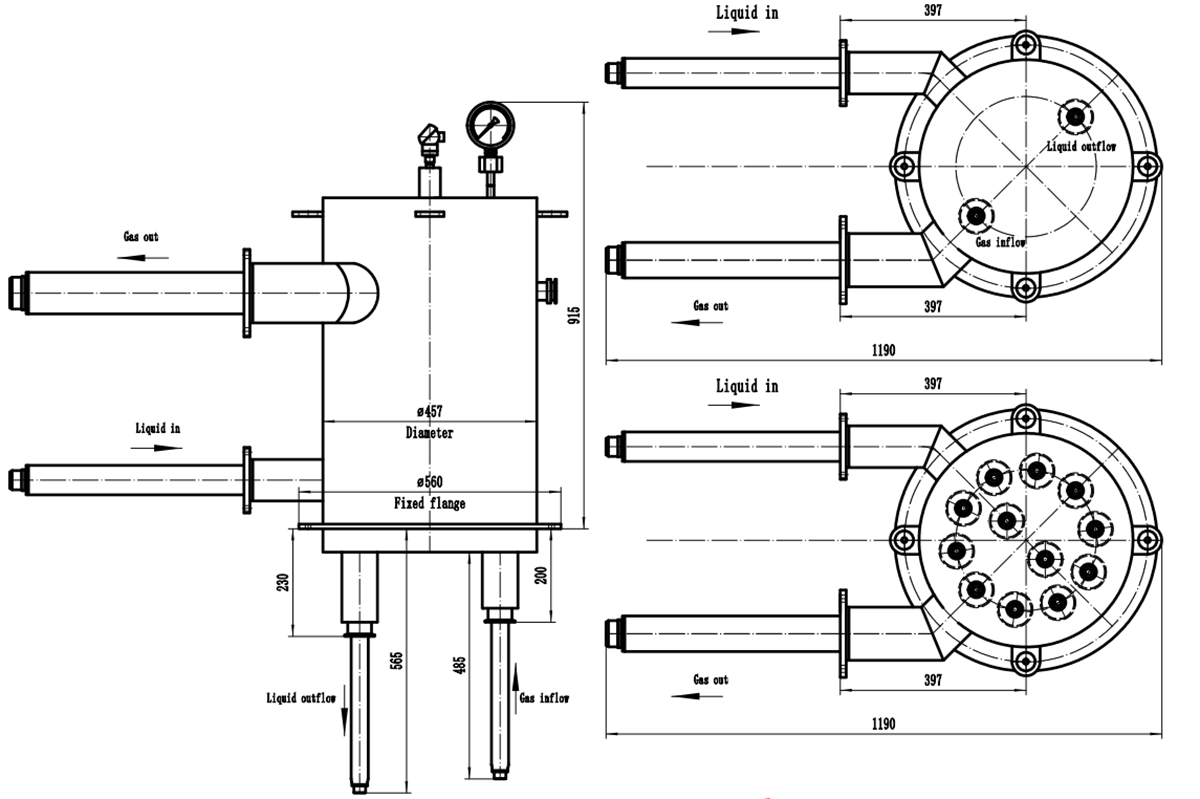

Multi-core Degasser rau HASS Daim Ntawv Thov

Lub tank cia kua nitrogen sab nraum zoov muaj ntau cov nitrogen vim nws khaws cia thiab thauj mus los hauv qab kev siab. Hauv lub kaw lus no, qhov kev thauj mus los ntawm cov kav dej ntev dua, muaj ntau lub luj tshib thiab kev tiv thaiv ntau dua, uas yuav ua rau muaj ib feem ntawm cov kua nitrogen. Lub raj nqus tsev rwb thaiv tsev yog txoj hauv kev zoo tshaj plaws los thauj cov kua nitrogen tam sim no, tab sis kev xau cua sov tsis zam tau, uas tseem yuav ua rau muaj ib feem ntawm cov kua nitrogen. Hauv kev xaus, cov kua nitrogen muaj ntau cov nitrogen, uas ua rau muaj kev tiv thaiv roj, ua rau cov kua nitrogen ntws tsis du.

Cov khoom siv tso pa tawm ntawm cov yeeb nkab nqus tsev, yog tias tsis muaj cov khoom siv tso pa tawm lossis tsis txaus cov pa tawm, yuav ua rau muaj kev tiv thaiv roj. Thaum cov roj tiv thaiv tau tsim, lub peev xwm xa cov kua nitrogen yuav raug txo qis heev.

Lub Multi-core Degasser tsim los ntawm peb lub tuam txhab tuaj yeem ua kom cov nitrogen tawm ntawm cov kav dej kua nitrogen tseem ceeb mus rau qhov siab tshaj plaws thiab tiv thaiv kev tsim cov roj tsis kam. Thiab Multi-core Degasser muaj qhov ntim sab hauv txaus, tuaj yeem ua lub luag haujlwm ntawm lub tank cia khoom, tuaj yeem ua tau raws li qhov xav tau ntawm qhov siab tshaj plaws ntawm cov kav dej kua.

Cov qauv tsim tshwj xeeb ntawm ntau lub hauv paus, muaj peev xwm ua pa tawm zoo dua li peb lwm hom kev sib cais.

Txuas ntxiv nrog tsab xov xwm dhau los, muaj qee qhov teeb meem uas yuav tsum tau xav txog thaum tsim cov kev daws teeb meem rau Lub Tshuab Nqus Tsev Insulated Piping System rau cov ntawv thov cryogenic hauv Kev Lag Luam Chip.

Ob Hom Kev Siv Lub Tshuab Nqus Tsev Uas Muaj Cov Khoom Siv Rwb Thaiv Tsev

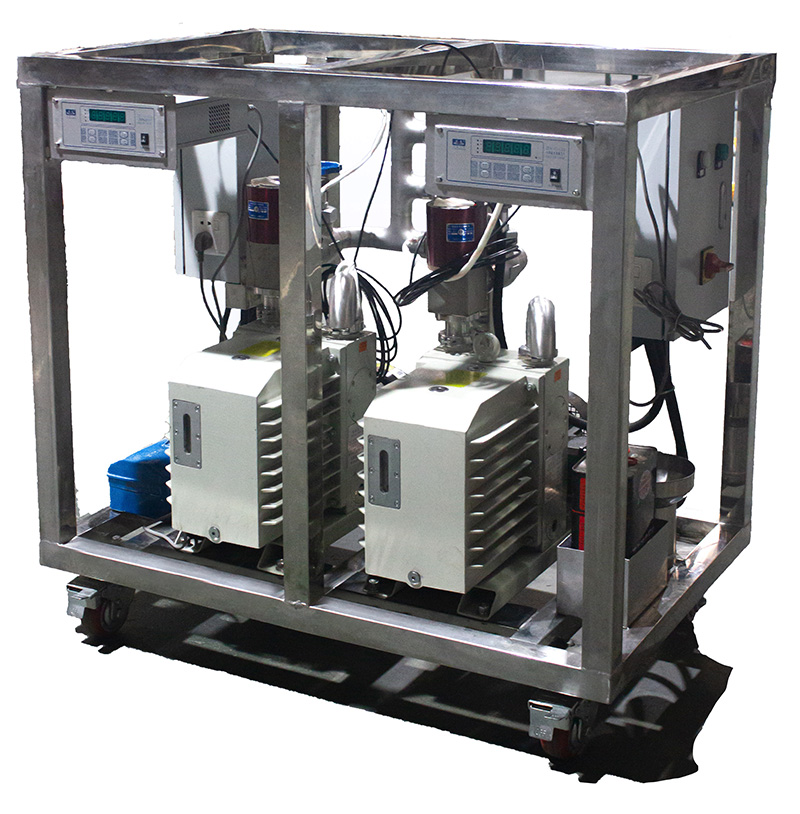

Muaj ob hom Vacuum Insulated Piping System: Static VI System thiab Dynamic Vacuum Pumping System.

Lub kaw lus VI ruaj khov txhais tau tias tom qab txhua lub yeeb nkab ua tiav hauv lub hoobkas, nws raug nqus tsev mus rau qib nqus tsev uas tau teev tseg ntawm lub twj tso kua mis thiab kaw. Thaum lub sijhawm teeb tsa thiab muab tso rau hauv kev siv, ib lub sijhawm twg tsis tas yuav rov qab mus rau qhov chaw.

Qhov zoo ntawm Static VI System yog tus nqi kho tsis kim. Thaum lub tshuab raj xa dej ua haujlwm lawm, yuav tsum tau kho ob peb xyoos tom qab. Lub tshuab nqus tsev no haum rau cov tshuab uas tsis xav tau kev txias txias thiab qhib rau kev kho hauv tsev.

Qhov tsis zoo ntawm Static VI System yog tias lub tshuab nqus tsev txo qis nrog lub sijhawm. Vim tias txhua yam khoom siv tso tawm cov pa roj me me txhua lub sijhawm, uas yog txiav txim siab los ntawm cov khoom siv lub cev. Cov khoom siv hauv lub tsho ntawm VI Pipe tuaj yeem txo cov pa roj uas tso tawm los ntawm cov txheej txheem, tab sis tsis tuaj yeem cais tawm tag nrho. Qhov no yuav ua rau lub tshuab nqus tsev ntawm qhov chaw kaw lub tshuab nqus tsev, yuav qis dua thiab qis dua, lub raj nqus tsev rwb thaiv tsev yuav maj mam ua rau lub peev xwm txias tsis muaj zog.

Lub Tshuab Nqus Tsev Dynamic txhais tau hais tias tom qab ua tiav cov yeeb nkab thiab tsim cov yeeb nkab, cov yeeb nkab tseem raug tshem tawm hauv lub Hoobkas raws li cov txheej txheem ntawm kev kuaj pom qhov xau, tab sis lub tshuab nqus tsev tsis raug kaw ua ntej xa khoom. Tom qab kev teeb tsa hauv thaj teb tiav lawm, cov txheej txheem nqus tsev ntawm txhua cov yeeb nkab yuav tsum txuas nrog ib lossis ntau chav los ntawm cov yeeb nkab tsis xeb, thiab yuav tsum siv lub twj tso kua mis me me tshwj xeeb los nqus cov yeeb nkab hauv thaj teb. Lub twj tso kua mis tshwj xeeb muaj lub kaw lus tsis siv neeg los saib xyuas lub tshuab nqus tsev txhua lub sijhawm, thiab nqus tsev raws li qhov xav tau. Lub kaw lus khiav 24 teev hauv ib hnub.

Qhov tsis zoo ntawm Dynamic Vacuum Pumping System yog tias lub tshuab nqus tsev yuav tsum tau tswj hwm los ntawm hluav taws xob.

Qhov zoo ntawm Dynamic Vacuum Pumping System yog tias qib nqus tsev ruaj khov heev. Nws yog siv rau hauv qhov chaw sab hauv tsev thiab qhov yuav tsum tau ua haujlwm nqus tsev ntawm cov haujlwm siab heev.

Peb lub Dynamic Vacuum Pumping System, tag nrho cov twj tso kua mis tshwj xeeb uas sib xyaw ua ke kom ntseeg tau tias cov khoom siv nqus tsev, qhov yooj yim thiab tsim nyog los xyuas kom meej tias cov nyhuv ntawm lub tshuab nqus tsev, qhov zoo ntawm cov khoom siv nqus tsev kom ntseeg tau tias qhov zoo ntawm lub tshuab nqus tsev.

Rau qhov project MBE, vim tias cov khoom siv nyob hauv chav huv, thiab cov khoom siv khiav ntev. Feem ntau ntawm cov kav dej nqus tsev nyob hauv qhov chaw kaw ntawm cov txheej nruab nrab ntawm chav huv. Nws tsis yooj yim sua kom siv cov kev saib xyuas lub tshuab nqus tsev ntawm cov kav dej yav tom ntej. Qhov no yuav muaj kev cuam tshuam loj heev rau kev ua haujlwm ntev ntawm lub system. Yog li ntawd, qhov project MBE siv yuav luag txhua lub Dynamic Vacuum Pumping System.

Lub Tshuab Pab Kom Siab

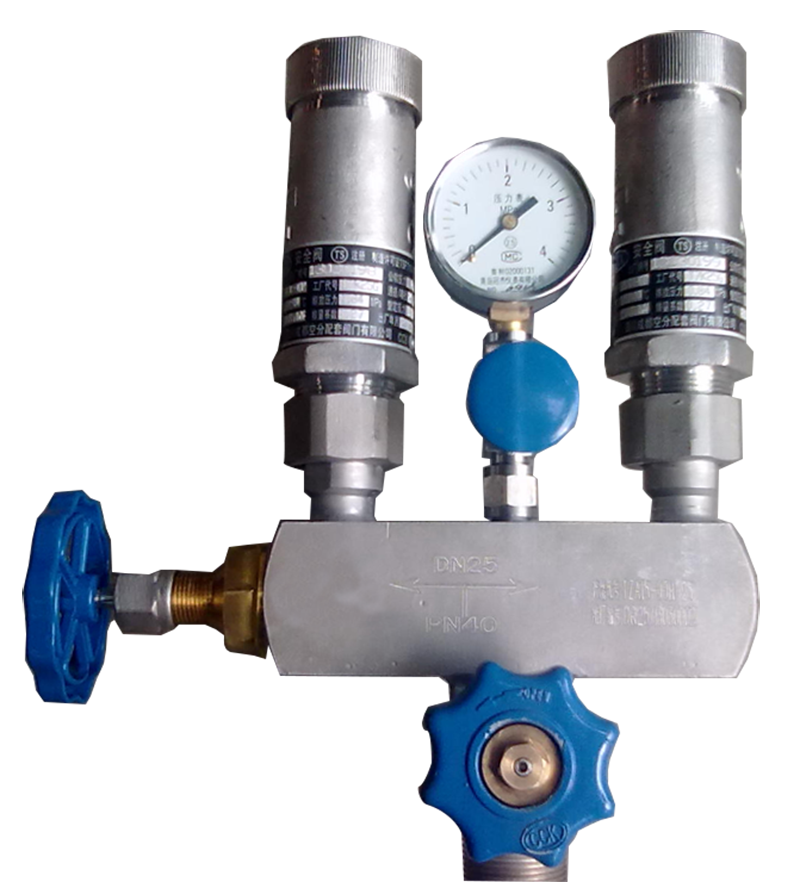

Lub kaw lus txo qhov siab ntawm cov kab tseem ceeb siv Safety Relief Valve Group. Safety Relief Valve Group siv ua lub kaw lus tiv thaiv kev nyab xeeb thaum muaj kev kub ntxhov ntau dhau, VI Piping tsis tuaj yeem hloov kho tau thaum siv li qub.

Lub Qhov (Safety Relief Valve) yog ib qho tseem ceeb uas yuav tsum tau ua kom lub raj xa dej tsis txhob muaj kev kub ntxhov ntau dhau, ua haujlwm tau zoo, yog li nws tseem ceeb heev rau kev ua haujlwm ntawm lub raj xa dej. Tab sis lub qhov (safety valve) raws li txoj cai yuav tsum tau xa mus xyuas txhua xyoo. Thaum siv ib lub qhov (safety valve) thiab lwm lub npaj lawm, thaum tshem ib lub qhov (safety valve) tawm, lwm lub qhov (safety valve) tseem nyob hauv lub raj xa dej kom ntseeg tau tias lub raj xa dej ua haujlwm tau zoo.

Pawg Lub Tshuab Pab Kom Muaj Kev Nyab Xeeb muaj ob lub Tshuab Pab Kom Muaj Kev Nyab Xeeb DN15, ib qho rau siv thiab ib qho rau sawv ntsug. Hauv kev ua haujlwm ib txwm, tsuas yog ib lub Tshuab Pab Kom Muaj Kev Nyab Xeeb txuas nrog VI Piping System thiab khiav ib txwm. Lwm lub Tshuab Pab Kom Muaj Kev Nyab Xeeb raug txiav tawm ntawm cov yeeb nkab sab hauv thiab tuaj yeem hloov pauv txhua lub sijhawm. Ob lub tshuab pab kom muaj kev nyab xeeb txuas nrog thiab txiav tawm los ntawm lub xeev hloov pauv sab.

Pawg Neeg Saib Xyuas Kev Nyab Xeeb muaj lub ntsuas siab los xyuas qhov siab ntawm cov kav dej txhua lub sijhawm.

Pawg Lub Qhov Cua Sov Kev Nyab Xeeb muaj lub qhov cua tso tawm. Nws tuaj yeem siv los tso cov pa tawm hauv cov yeeb nkab thaum ntxuav, thiab cov pa nitrogen tuaj yeem tso tawm thaum lub kaw lus kua nitrogen khiav.

Cov Khoom Siv Cryogenic HL

HL Cryogenic Equipment uas tau tsim muaj xyoo 1992 yog ib lub npe koom tes nrog Chengdu Holy Cryogenic Equipment Company hauv Suav teb. HL Cryogenic Equipment tau cog lus rau kev tsim thiab tsim cov High Vacuum Insulated Cryogenic Piping System thiab lwm yam khoom siv txhawb nqa.

Hauv lub ntiaj teb niaj hnub no uas hloov pauv sai heev, kev muab cov thev naus laus zis siab heev thaum ua kom cov neeg siv khoom txuag tau nyiaj ntau tshaj plaws yog ib txoj haujlwm nyuaj. Tau 30 xyoo, HL Cryogenic Equipment Company hauv yuav luag txhua yam khoom siv cryogenic thiab kev lag luam muaj kev paub tob dua hauv kev siv, tau khaws cov kev paub nplua nuj thiab txhim khu kev qha, thiab tshawb nrhiav thiab siv zog ua kom tau raws li cov kev txhim kho tshiab hauv txhua qhov chaw ntawm lub neej, muab cov neeg siv khoom nrog cov kev daws teeb meem tshiab, siv tau thiab ua haujlwm tau zoo, ua rau peb cov neeg siv khoom sib tw ntau dua hauv kev ua lag luam.

For more information, please visit the official website www.hlcryo.com, or email to info@cdholy.com .

Lub sijhawm tshaj tawm: Lub Yim Hli-25-2021